edge.SHIELDOR: Elevating Manufacturing Security with Resilience

Recognized in the Category:

Photo Gallery

|

|

edge.SHIELDOR: Elevating Manufacturing Security with Resilience

Additional Info

| Company | TRIOVEGA GmbH |

| Company size | 50 - 99 employees |

| World Region | Europe |

| Website | https://triovega.com/ |

NOMINATION HIGHLIGHTS

Cyberattacks in manufacturing are on the rise, leading to significant financial losses, especially due to ransom demands and machine downtime. Conventional security measures in the field of operational technology (OT) are insufficient to protect manufacturing environments from cyberattacks. Recognizing this challenge, TRIOVEGA developed edge.SHIELDOR, an innovative, patent-pending solution.

By deploying edge.SHIELDOR, information technology (IT) networks are completely and sustainably separated from operational technology (OT) networks. This effectively denies potential cybercriminals access to the IT network and minimizes disruptions in production. At the same time, this separation ensures secure data exchange while eliminating the need for extensive retrofits or software updates for older plants. Consequently, edge.SHIELDOR promotes the secure operation of both existing and new manufacturing facilities, significantly extending their lifespan.

Another major advantage of this solution is its interoperability, allowing users to integrate existing production software components into this security concept. As a result, edge.SHIELDOR significantly simplifies the complexity associated with managing OT security measures in the manufacturing sector.

Key Capabilities / Features

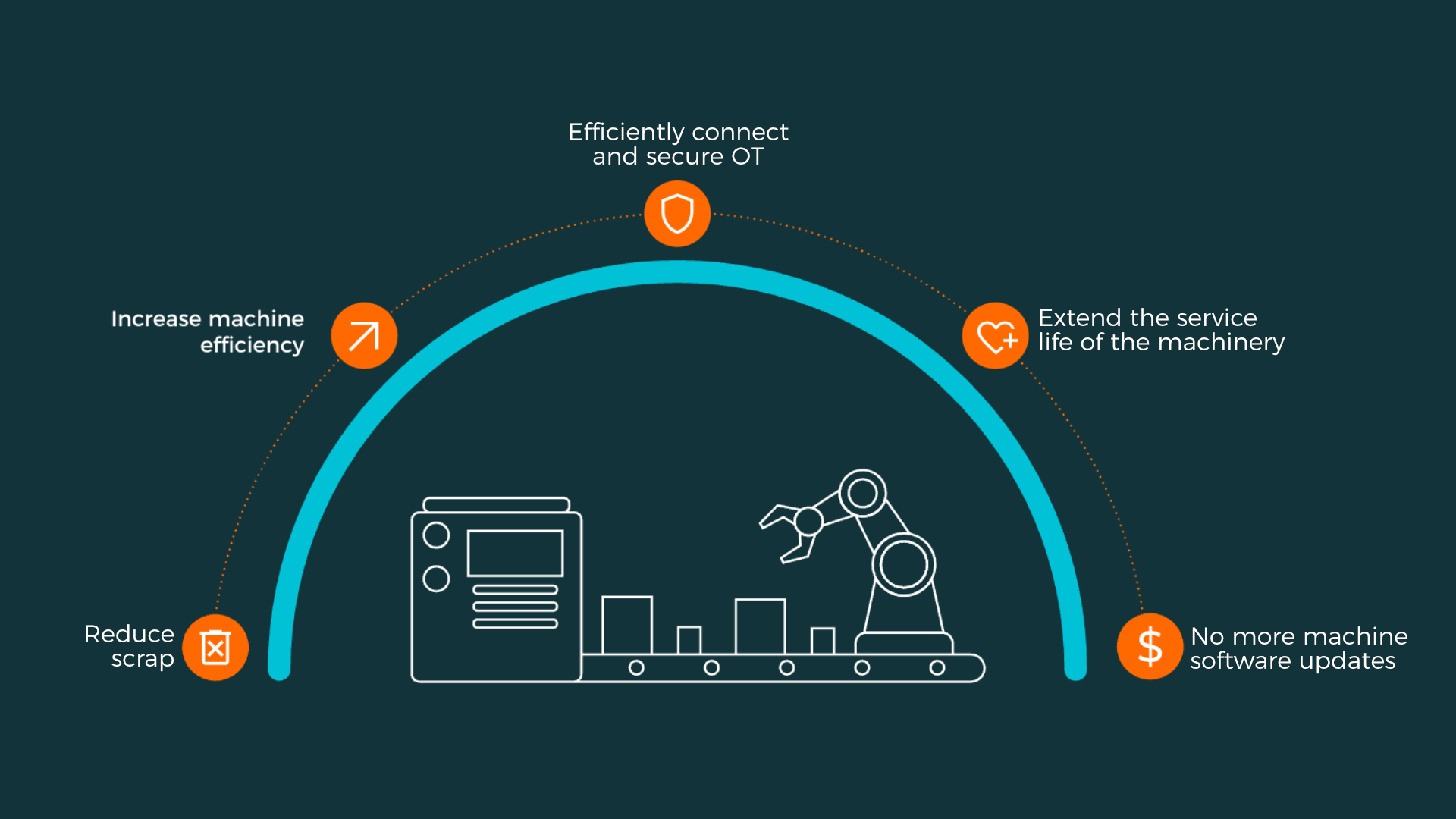

The concept behind edge.SHIELDOR resembles a protective glass dome for manufacturing machines, shielding them from harm and securing them directly at the edge, all while ensuring data transparency. By efficiently connecting and securing Operational Technology (OT), edge.SHIELDOR offers robust protection against potential threats, thereby strengthening overall system security.

By implementing edge.SHIELDOR, users can expect a reduction in scrap, leading to savings in resources and time. Additionally, machine efficiency increases, enhancing overall performance.

By supporting various protocols, edge.SHIELDOR can seamlessly integrate both older and newer plants into an existing corporate network. Consequently, the solution contributes to extending the service life of machines, promoting their longevity and reliability.

The performance spectrum of edge.SHIELDOR enables manufacturing companies to sustainably reduce their CapEx costs by eliminating the need for retrofitting measures and extending asset software-based lifecycles. Furthermore, by potentially saving up to 80% in risk mitigation costs for OT security measures, it also leads to a permanent reduction in OpEx costs.

A centralized management enables the integration of all manufacturing plants, with optional authentication mechanisms for added security. Automated update routines ensure continuous compliance with the latest security standards, enhancing long-term protection.

edge.SHIELDOR simplifies the process of updating and securing manufacturing machines, without disrupting ongoing production or having to rely on maintenance windows. Consequently, the necessity for machine software updates is eliminated with edge.SHIELDOR.

How we are different

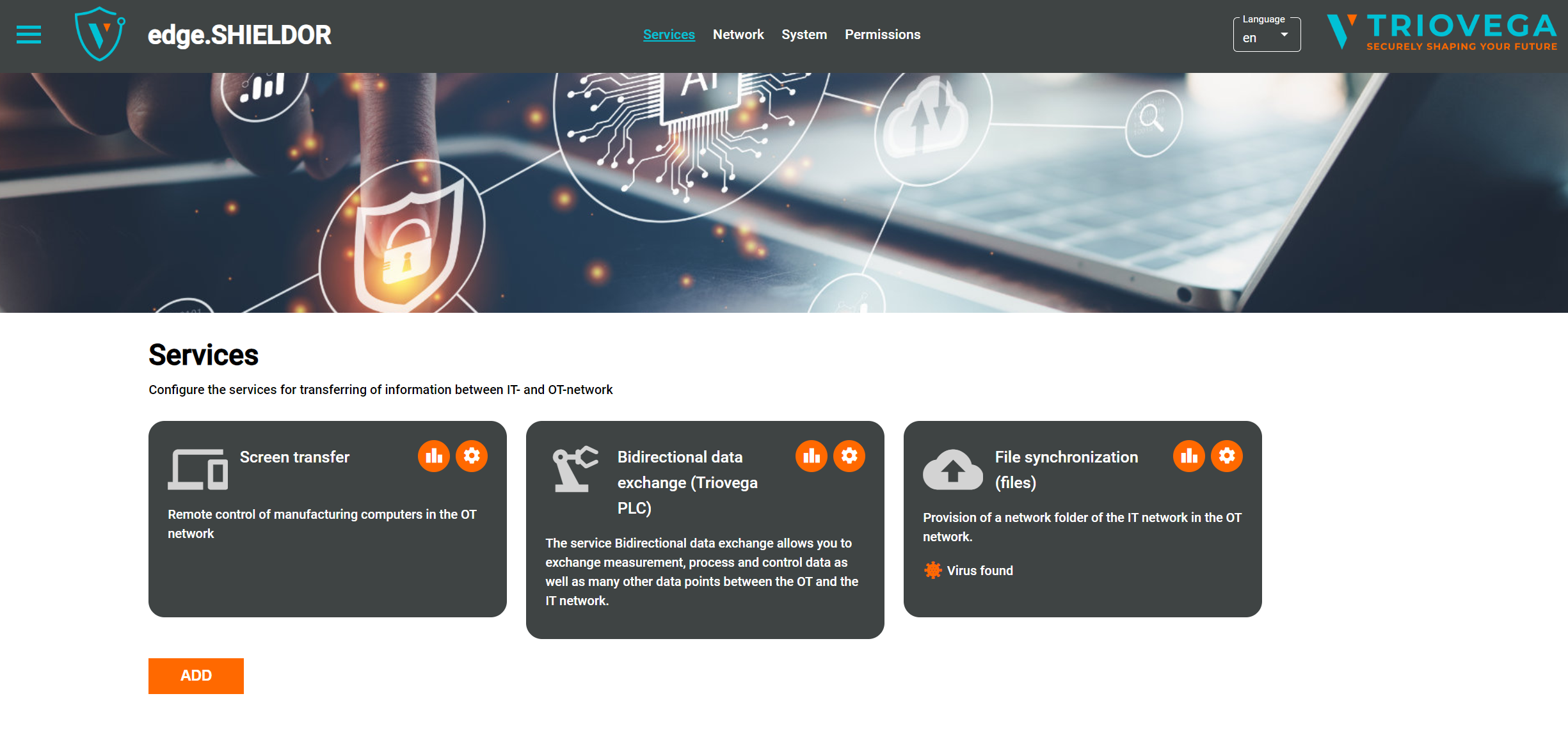

1. In contrast to competing solutions, edge.SHIELDOR stands out with a holistic patent-pending security approach that integrates various aspects such as network security, protocol conversion in the form of bidirectional process data transfer and file synchronization, as well as compliance with international standards.

2. As to our knowledge, edge.SHIELDOR is the only solution applicable without peripherals (i.e. deployed on virtual machines). This advantage enhances security without requiring additional physical IT assets (e.g., IPC) that also need maintenance or installation.

3. Furthermore, third-party software can be utilized within the established container structures. This means that additional tools or scripts can be installed and used directly within the containers, in order to eliminate the bypassing of the security concept.

Vote by Sharing

- Like

- Digg

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- SMS

- Viber

- Telegram

- Subscribe

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Each completed social share counts as a vote for this award nomination.