OTORIO’s Risk Management Solutions Secure Manufacturing Operations

Recognized in the Category:

Photo Gallery

|

|

OTORIO's Risk Management Solutions Secure Manufacturing Operations

Additional Info

| Company | OTORIO |

| Company size | 50 - 99 employees |

| World Region | Middle East |

| Website | https://www.otorio.com/ |

NOMINATION HIGHLIGHTS

Today’s increased interconnectivity and data sharing between systems and networks in the production, supply chain, transportation, and end-user consumption, expands the attack surface for both manufacturers and consumers and increases risk.

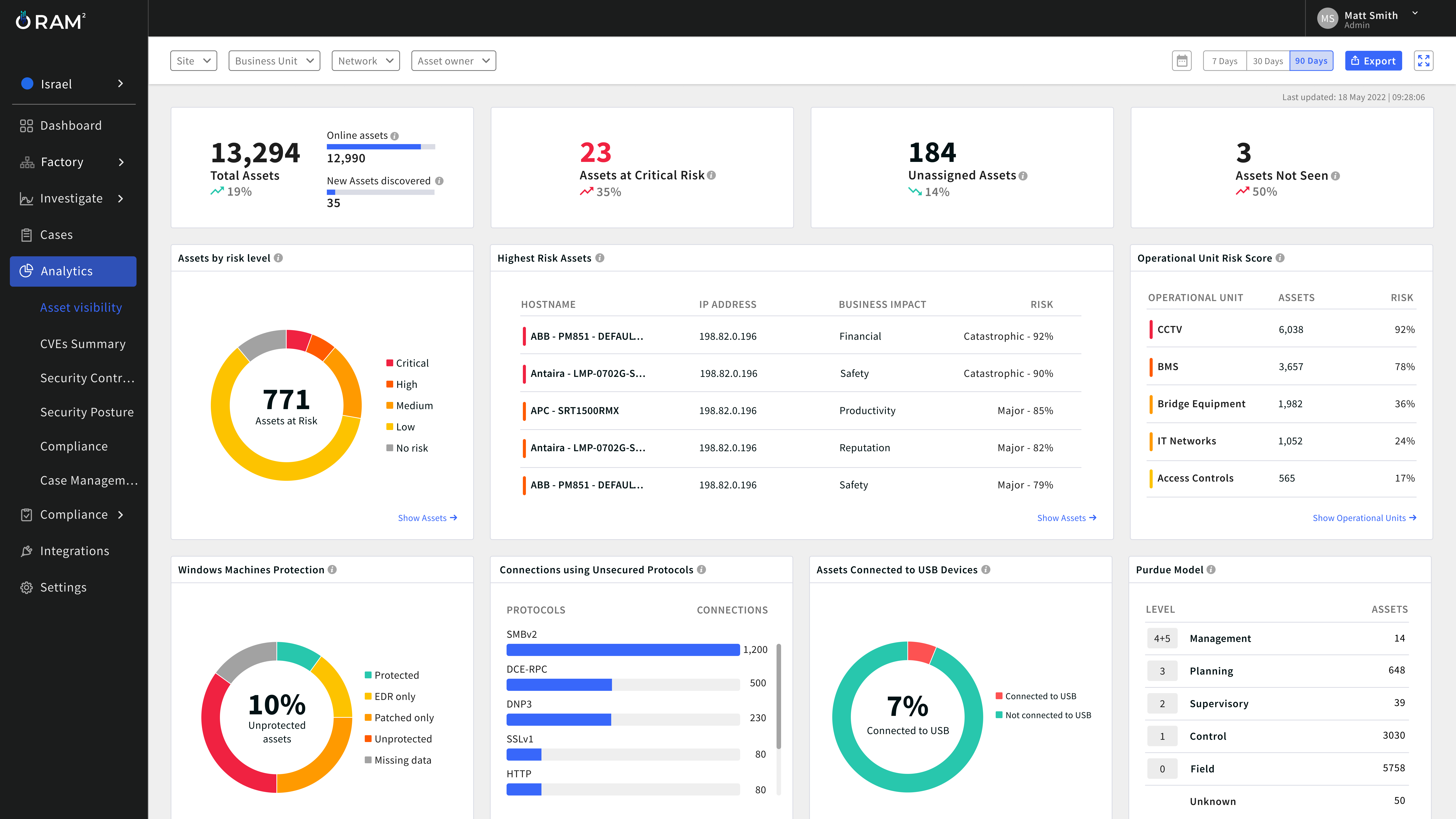

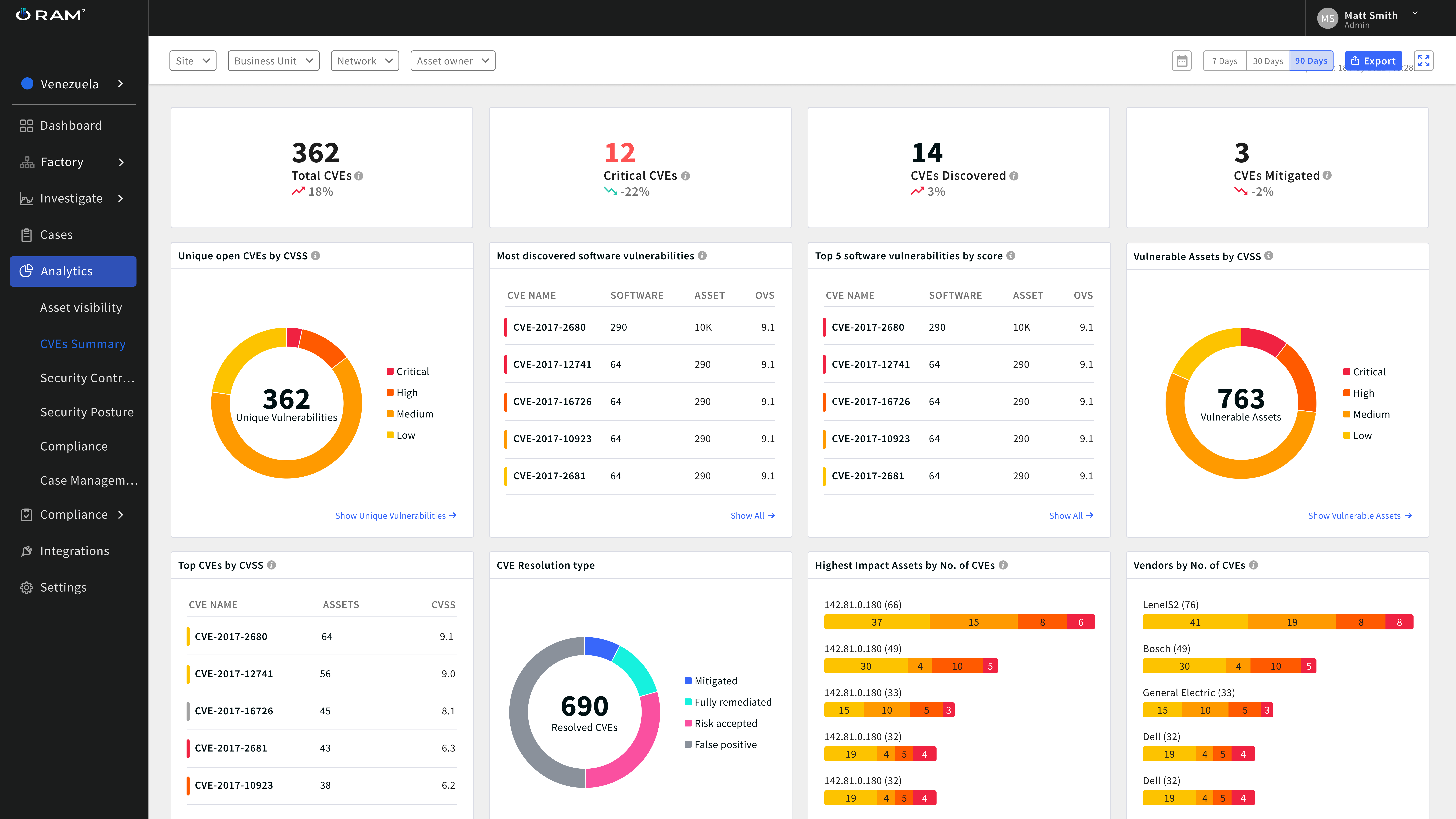

OTORIO’s OT cyber risk management platform is tailored to the needs of the manufacturing industry, whether it pertains to process or discrete manufacturing. Our solutions are designed and built from the ground up with safety, reliability and resilience of operations as top priority. OTORIO’s platform merges cyber and physical systems into one source of truth. This provides different domain owners with an accurate and common viewpoint of the business-related cyber risks in their operational environment, enabling better security management decision making while maximizing the ROI from operational security controls and processes. Starting with consolidated and advanced visibility of all operations (IT-OT-IIoT) assets, the platform provides operational context, and impact driven prioritization of the most critical risks in the plant. Additionally, OTORIO’s solution supports

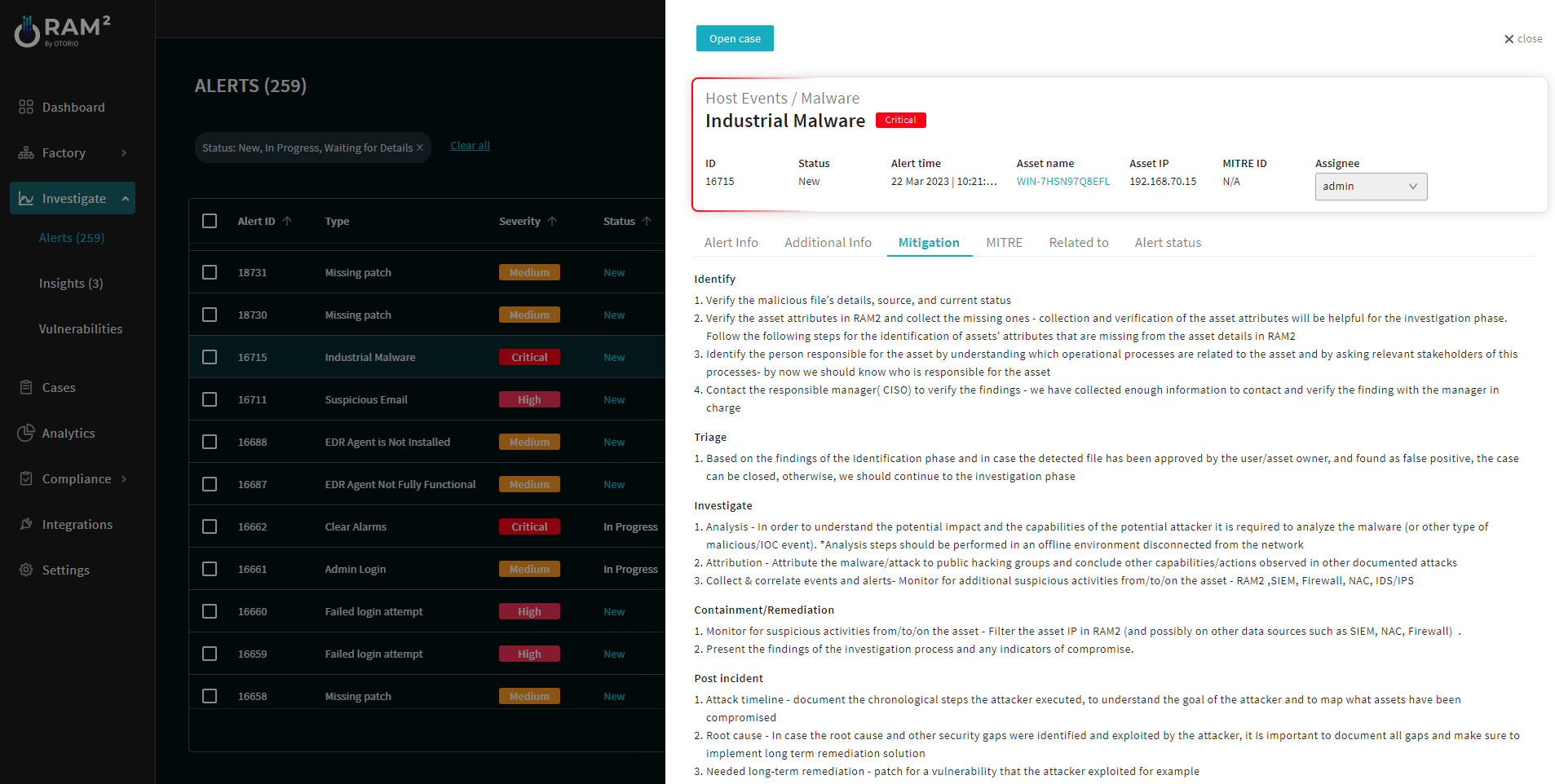

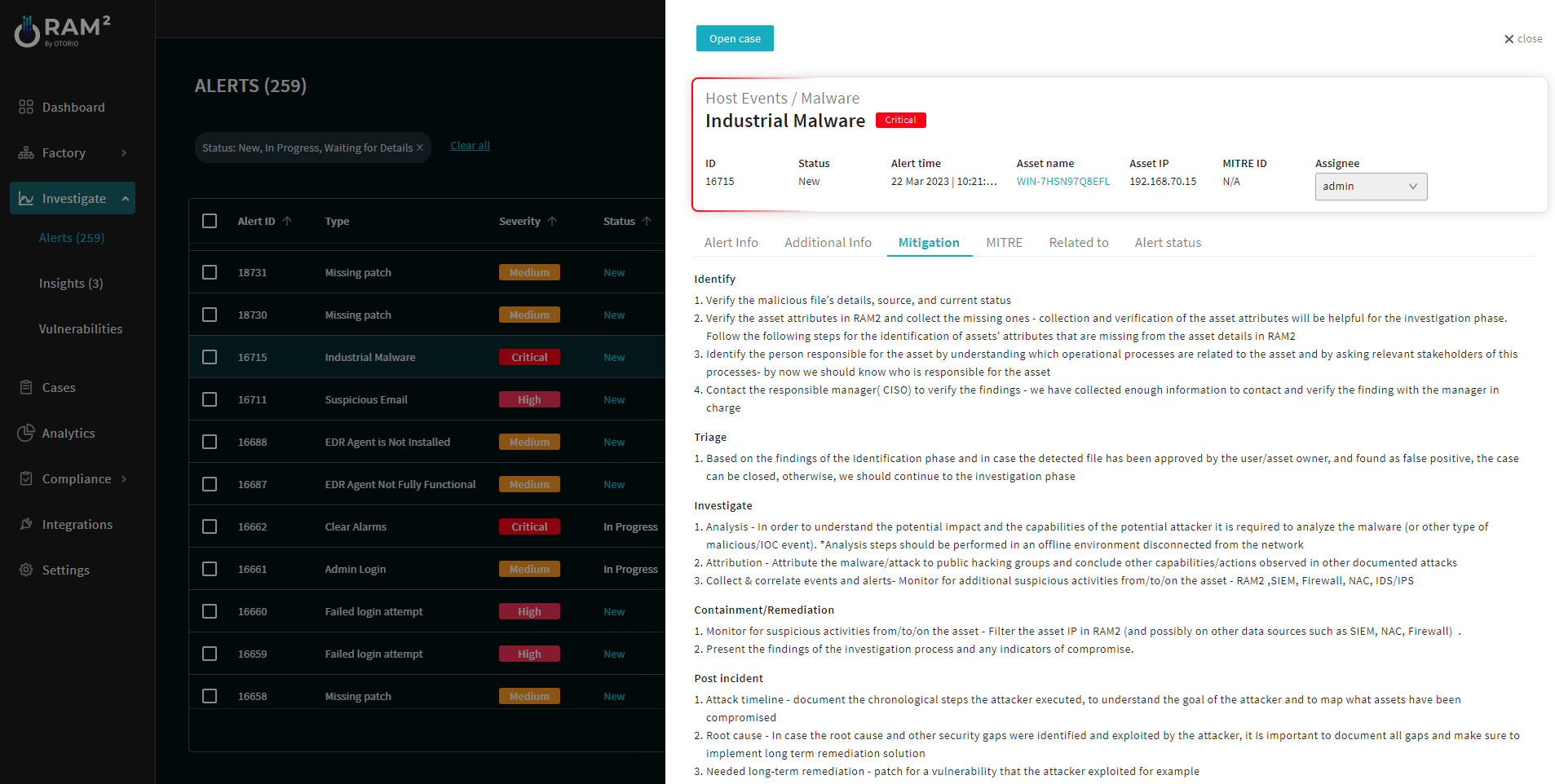

common industry security standards and regulations by providing automated, out-of-the-box asset and site-level compliance assessment. This assessment is based on a recognized framework and best practices, enabling security managers to govern policy-based OT security frameworks and comply with industry regulations. The concise compliance and risk assessment reports include clear, actionable mitigation steps tailored to the unique operational environment, internal processes and unique manufacturing characteristics. OTORIO’s solution leverages existing security controls while reducing noise and alert fatigue in the manufacturing environment.

OTORIO’s solution includes patented Attack Graph Analysis technology for exposure-based risk prioritization, seamlessly integrated into its powerful Cyber Digital Twin model. This technology enables organizations to visualize inter-process communication, identifies potential attack path vectors and conduct advanced risk assessments, providing a prioritized recommendations report for immediate risk reduction. This feature allows organizations to prioritize and address risks effectively, with a special focus on critical mitigation actions.

Key Capabilities / Features

OTORIO's industrial-native OT cyber risk management platform is tailored to meet the unique needs of the manufacturing sector, providing consolidated visibility of all operational assets, business impact-driven risk prioritization, and prescriptive mitigation steps. This solution bridges the gap between different domains and functions, enabling manufacturing companies to confidently digitize processes without compromising safety, reliability, or efficiency.

Enable safe digitalization and modernization:

* Protecting interconnected modern equipment and legacy systems, without compromising on the safety of operations.

* Providing centralized risk overview across the different business domains: OT, IT, Executive management, Governance risk and compliance.

* Automated visibility, orchestrating data from existing security controls.

* Reducing noise and alert fatigue.

* Preventing unauthorized access that may result in shutdown of systems, late delivery of essential raw materials and financial loss, or even environmental damage and threat to human life.

Prevent disruption and ensure operational availability:

* Assessing network segmentation to ensure that OT manufacturing systems can

continue to operate safely if an IT system has been compromised, vice versa.

* Securing the increasing attack surface with improved access control against

unauthorized manipulation of manufacturing systems.

* Empowering OT security teams to prevent successful ransomware attacks with

prescriptive playbooks for risk mitigation and hardening of assets.

* Impact-driven prioritization of risk mitigation actions.

Improve OT security operations efficiency:

* Automating OT Security operations.

* Continuously monitors cross-domain data sources to identify potential breaches.

* Tailored to network architecture and capable of covering systems and vendors with

direct impact on the manufacturing supply chain, process, transportation and the output consumed by the customers.

* Automated network segmentation assessment.

* Out-of-the-box compliance audit for ever-changing regulation and standards (e.g., NIST).

* Implementing a risk-based approach to reduce the risk of exploitation of unpatched

systems.

* Empowering security practitioners to proactively reduce risk, without compromising

safety.

How we are different

* Innovative OT Cyber Risk Management: The OTORIO platform is a groundbreaking solution that redefines how Manufacturing secure interconnected systems in the operational environment while ensuring operational safety using OTORIO's context risk-based prioritization, which helps Manufacturing focus on the most important, highest-priority mitigation actions first to ensure the safety and efficiency of their operational processes. It also provides actionable mitigation playbooks, setting a new standard in safeguarding operational networks.

* Pioneering Exposure-based Prioritization Leveraging a Cyber-Digital-Twin Technology for Non-Intrusive Attack Vectors Analysis: OTORIO's Cyber Digital Twin, along with the unique Attack Graph Analysis technology, provides dynamic visual network topology and advanced risk assessment capabilities. This innovation earned OTORIO a recent patent from the USPTO, solidifying its pioneering role in the OT security market.

* Proactive Risk Management and Business Value: OTORIO's OT approach, coupled with the platform's ease of integration and scalability, offers continuous OT cyber risk management with comprehensive visibility of manufacturing legacy and modern systems, DCS, control access, etc. It not only saves Manufacturing organizations time and resources but also improves operational efficiency and reliability, ensuring compliance with OT security regulations and standards as NIS2, NIST 800-82 and IEC 62443 and more while staying ahead of emerging threats.

Vote by Sharing

- Like

- Digg

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- SMS

- Viber

- Telegram

- Subscribe

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Each completed social share counts as a vote for this award nomination.